Truck accident in Potsdam

Towing service & procedure (RKA Potsdam)

If a truck is no longer roadworthy after an accident, one thing matters above all: securing the scene and fast, technically sound recovery to protect traffic, cargo, and the environment and to clear the roadway as quickly as possible. RKA Abschleppdienst Potsdam provides support 24/7 – from site protection to heavy recovery, including crane/winch technology and documentation.

Immediate actions for drivers / dispatch

- Personal safety first: hazard lights, high-visibility vest, secure the area – and avoid the danger zone (especially with cargo/leaks).

- Call emergency services (112) in case of injuries, fire, leaking operating fluids/hazardous goods.

- Provide precise location details: motorway/federal road, direction of travel, kilometre marker, next exit, landmarks. (RKA typically requests this information.)

abschleppdienstpotsdam.com - Collect key facts: vehicle type (articulated truck/rigid with trailer), loaded/unloaded, type of cargo, axle/steering capability, hazardous materials, whether the vehicle is in a ditch or overturned.

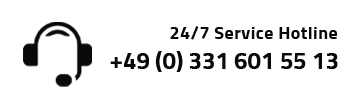

RKA Potsdam – contact & service area

RKA Abschleppdienst Potsdam GmbH

Am Silbergraben 20, 14480 Potsdam

24/7 emergency line: 0331 601 55 13

Mobile: 0172 167 13 06

E-mail:

Region Potsdam & main routes:

Potsdam and districts, including Werder (Havel), Michendorf, Nuthetal, Beelitz, Schwielowsee, Teltow/Kleinmachnow/Stahnsdorf as well as A10 (Berlin Ring), A9, B1/B2/B273.

Procedure after a truck accident – from dispatch to handover

1) Emergency call / assignment & dispatch

- Collection of incident data (location, situation, vehicle, cargo, hazards).

- Operational planning: selection of personnel, safety concept, and equipment (e.g. heavy recovery vehicle, winches, crane, air cushions, special rigging).

- Coordination with authorities/emergency services if traffic lanes or public space are affected (police/fire brigade/road authority).

2) Arrival & site securing

- Securing the accident site (traffic and hazard area) – in cooperation with police/fire services. SSM

- Key occupational safety rule: No persons in the danger zone of ropes/chains/winches; secure recovery vehicles against tipping or rolling. SSM Arbeit Safety

3) Situation assessment & recovery planning (decisive for damage-minimised operations)

On site, the following is assessed systematically:

- Vehicle position: on wheels, in ditch, embankment, guardrail, rollover/overturn, frame/trailer tension.

- Roadworthiness: rollable/steerable or not (determines towing vs. recovery/loading). DGUV publications

- Cargo: type, weight, centre of gravity, load securing, risk of shifting/leakage (possible transloading/cargo recovery).

- Environmental/hazard situation: diesel/oil, coolant, battery/HV systems, fire risk, unstable ground.

4) Technical execution: recovery / uprighting / loading / transport

Depending on the situation, one or more methods are combined:

A) “Standard” towing (if fundamentally rollable/steerable or technically preparable)

- Towing preparation (e.g. checking axles/steering, securing loose parts, technical measures for damage-minimised transport). RKA also offers towing preparation and transport to workshop/desired destination.

B) Recovery (if not rollable/steerable, in ditch/on embankment, stuck, heavily damaged)

- DGUV definition: uprighting, pulling out and loading (including by crane) of vehicles that are no longer rollable and/or steerable. DGUV publications

- Use of heavy recovery vehicles, rope and winch systems and – depending on the situation – crane and air cushion systems.

C) Uprighting overturned trucks (controlled, shock-free, with load management)

RKA typically describes the process in four steps:

- Securing & analysis (risk of sliding movements/leaks/unstable cargo)

- Selection of technology (crane, winch, pulleys, rigging)

- Step-by-step uprighting & stabilisation

- Transport & completion work (transloading/cleaning/documentation if required)

D) Crane & winch technology (when space/ground/loads require it)

- Suitable for overturned/fallen vehicles, limited space, unstable ground, or when standard tow trucks are insufficient.

- Typical components: winch(es) with redirection, controlled load movement, rigging/lifting gear, possibly a mobile crane.

Core safety points during technical operations (critical due to highest risk):

- No one in the danger zone of pulling equipment (rope/chain/winch).

- Secure recovery vehicles against tipping/rolling; when traffic is affected, coordinate with police/road authority. SSM Arbeit Safety

5) Clearance, cleaning, traffic release

- Objective: rapid reopening of the roadway (identified by RKA as a key service component).

- Important practical note from towing guidelines: Larger cleaning measures (e.g. wet cleaning/sweeper) are often decided by authorities and are not automatically part of a standard assignment. abschleppzentrale.de

6) Handover & documentation

- Handover to workshop, depot, impound lot, or destination of choice; upon request, operation documentation for insurers.

Read more: Technical procedures